Enclosed Print & Apply

Cody Heiser • April 5, 2023

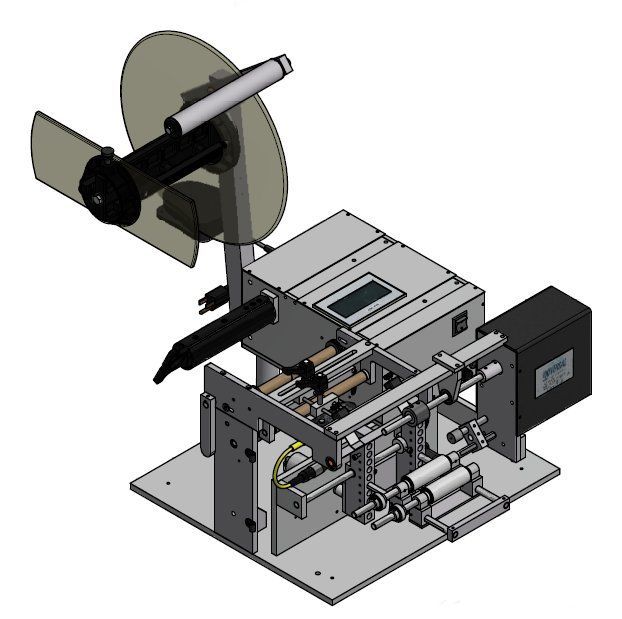

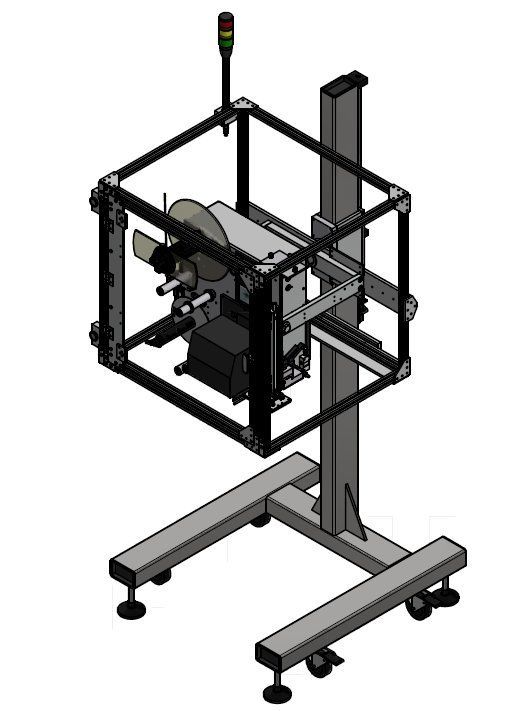

A Printer Applicator with a Dust Enclosure and Positive Air Pressure to keep the elements out

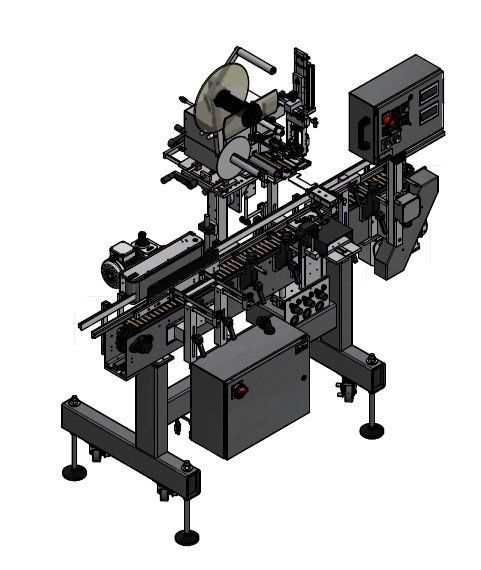

The UPA II Printer Applicator, with a protective dust cover, keeping the machine clean from the plant’s elements. The enclosure includes positive air pressure to reduce the dust molecules from entering the enclosure. The UPA II is equipped with a Sato print engine, and is mounted on a custom U base stand, The 81” upright column allows the tamp head to be at a height up to 51” off the floor.

The UPA II is PLC controlled, operated via a user-friendly touch screen. The tamp head includes a proximity sensor, and has multiple ports, enabling it to apply two additional label sizes. The unit also includes a 3 tier light tree with low label detection.

The UPA II Printer Applicator is a labeling system that can handle any product identification challenge. Whether you need to print and apply labels with barcodes, pricing, sizing, branding, or any other information, the UPA II can do it with speed and accuracy. You can choose from different print engines from leading manufacturers such as Sato, Zebra, or TSC, and design your own labels with labeling software. The UPA II is fully automatic and PLC controlled, with an easy-to-use touch screen and a quick change tamp head. It also has a label out detection feature and a 12” roll capacity on 3” core.

But what makes this UPA II stand out from other labeling systems is its protective dust cover with positive pressure. This feature keeps the machine clean from the plant’s elements, such as dust and debris, that can affect the quality of your labels and the maintenance cycle of the machinery.

If you are looking for a reliable and durable printer applicator that can keep your labels clean and clear, look no further than the UPA II with dust cover. This labeling system can handle your product identification needs, with a variety of print engines, label sizes, and tamp head options. The dust cover protects the machine from the plant’s elements, ensuring the quality and consistency of your labels.

Don’t let dust and debris ruin your labeling process. Contact us today and get a quote for the UPA II with dust cover, the ultimate labeling solution for your business.

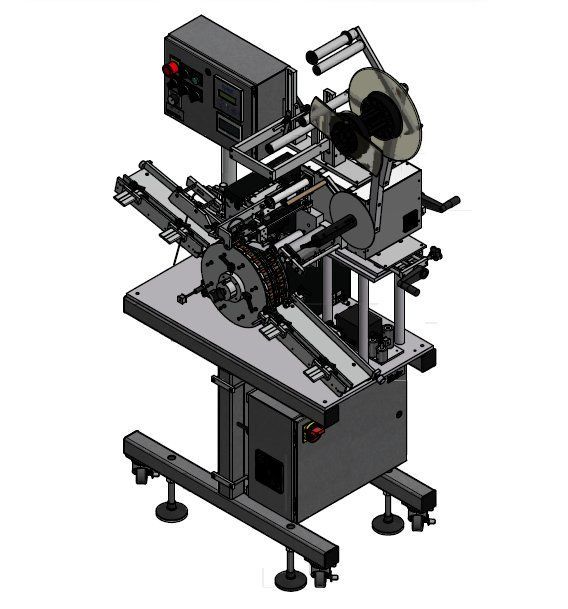

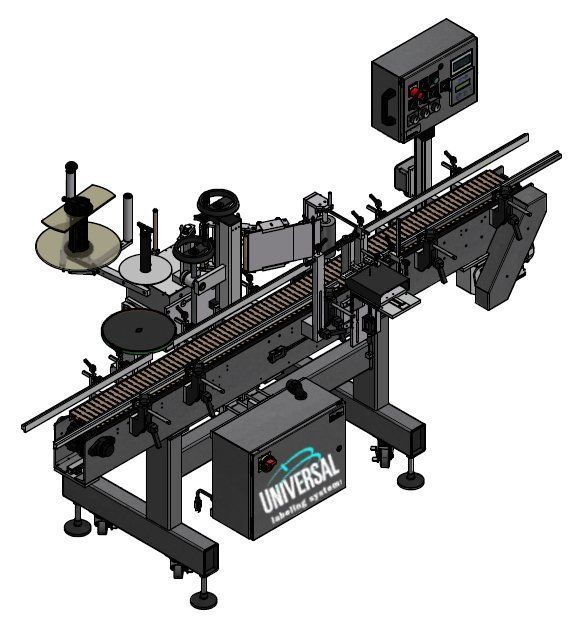

This R322 system automatically applies pressure sensitive labels to a variety of paint cans from one gallon’s to 12 ounce spray cans. The round product system is equipped with a wide label SL2000 label applicator (web widths up to 8.125”/207mm). The system includes a product encapsulator to accurately and synchronously adhere synthetic labels.

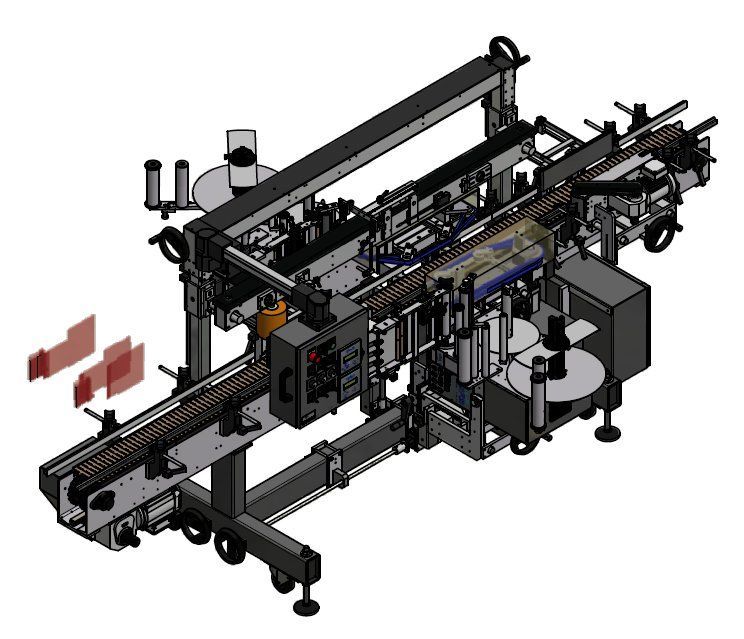

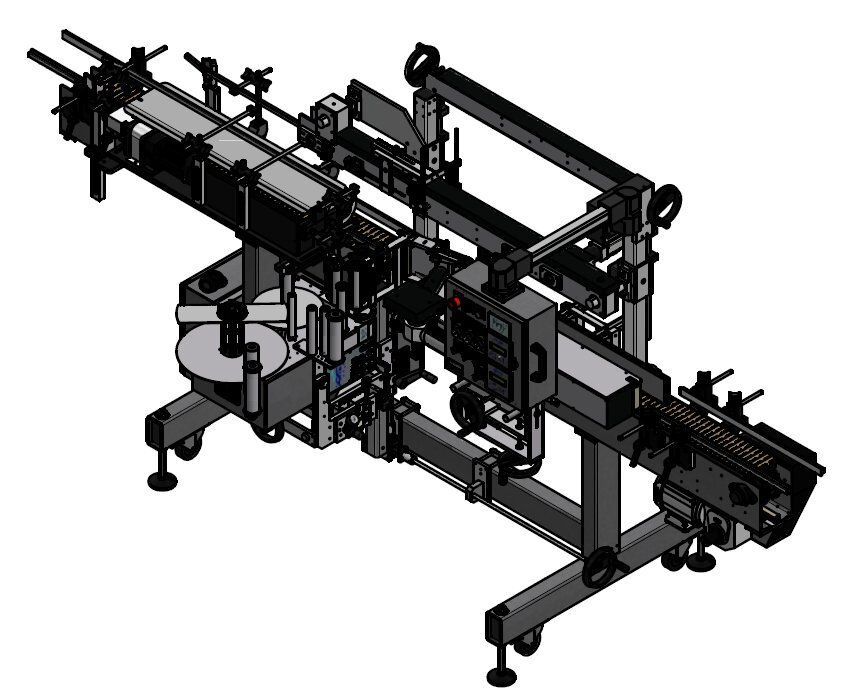

This automatic system automatically applies die cut pressure sensitive labels as a cap strap to a square liquor bottle. Upon detection by the photoelectric product sensor, the bottle is stopped and controlled by a pneumatic fixture and the label is tamped to the top and wiped down the neck. The wipe-down is achieved via a folding tamp head. Production speeds up to 40 products per minute.

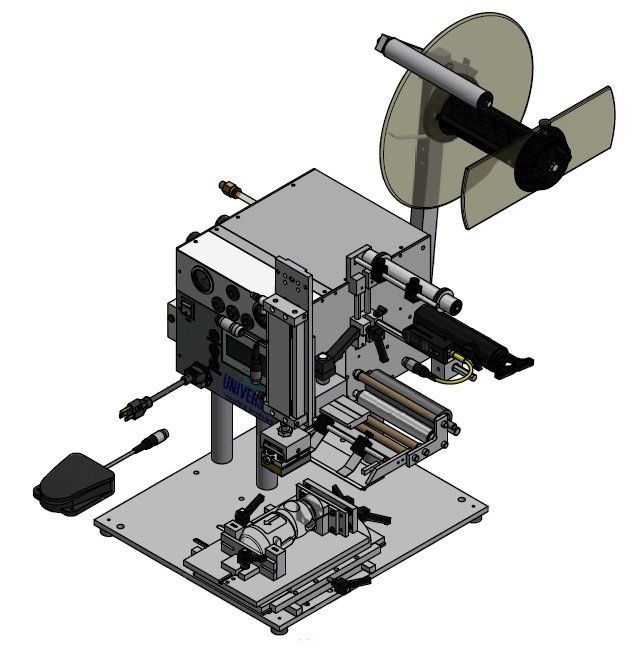

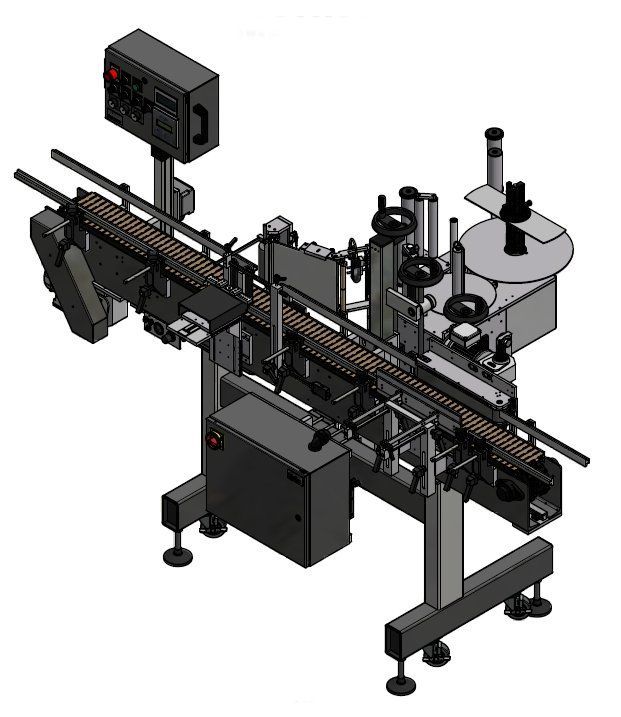

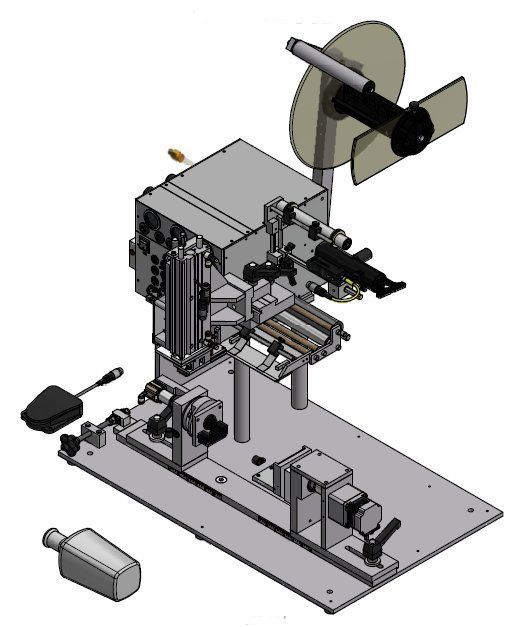

Looking for a reliable and efficient way to label your alcohol bottles? Look no further than our L60 Tamp label applicator with a rotary mechanism! Designed to make labeling your bottles a breeze, this machine features a simple yet effective clamping fixture that securely holds your bottle in place while a tamp head with the label travels to make contact. As the label meets the spinning bottle, it wipes on the label with ease, resulting in a smooth and accurate application every time. This stepper-driven rotary ensures the label center is oriented with the front of the bottle. Also, the fixture can be quickly changed to accommodate different bottle styles. Perfect for small businesses or short-run products, our L60 Tamp Rotary semi automatic label applicator is both speedy and accurate, ensuring that your bottles are labeled quickly and precisely. With its user-friendly design and reliable performance, this machine is the perfect solution for all your labeling needs. A semi-automatic system to apply a label to the neck of the 2 sizes of liquor bottles oriented to the body label. When the operator depresses the footswitch, the fixture rotates, applying the label around the neck in its proper position.