By Cody Heiser

•

May 2, 2023

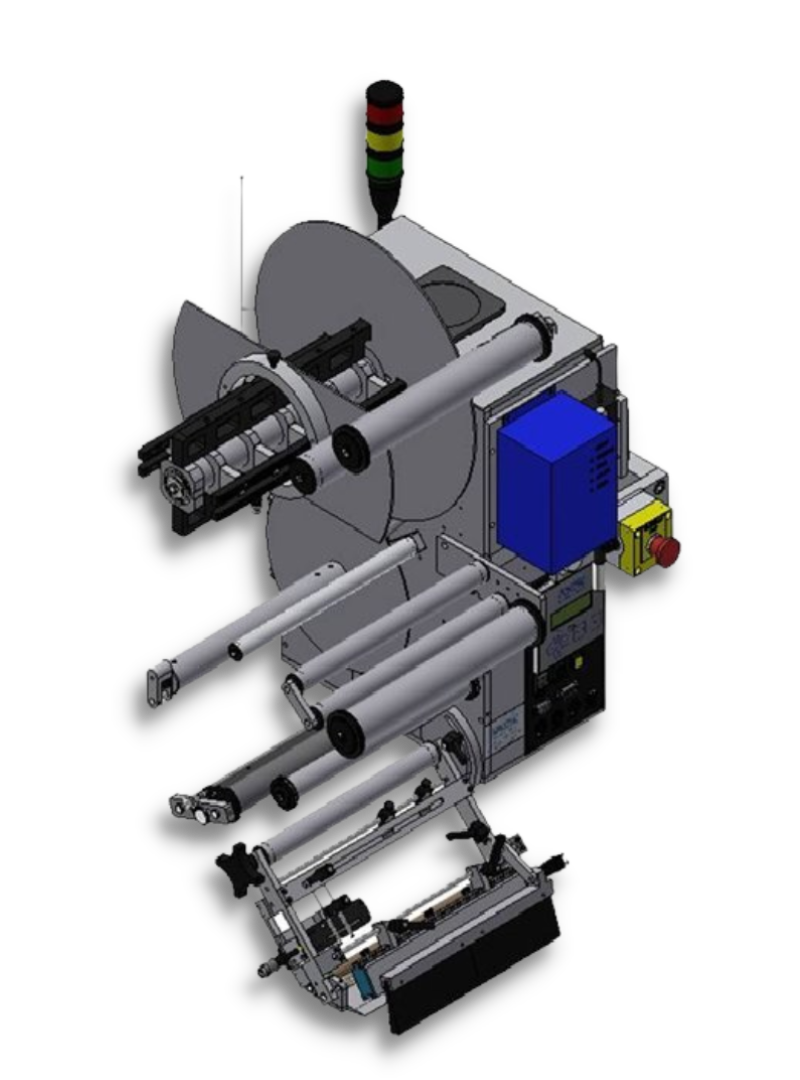

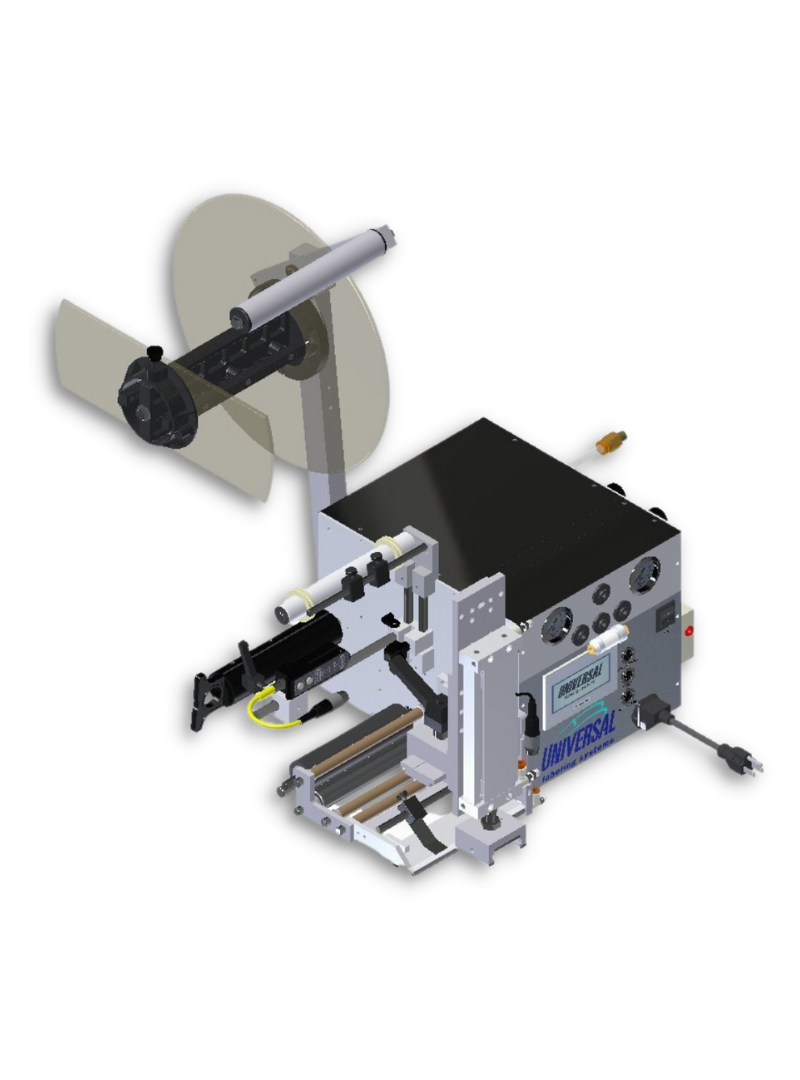

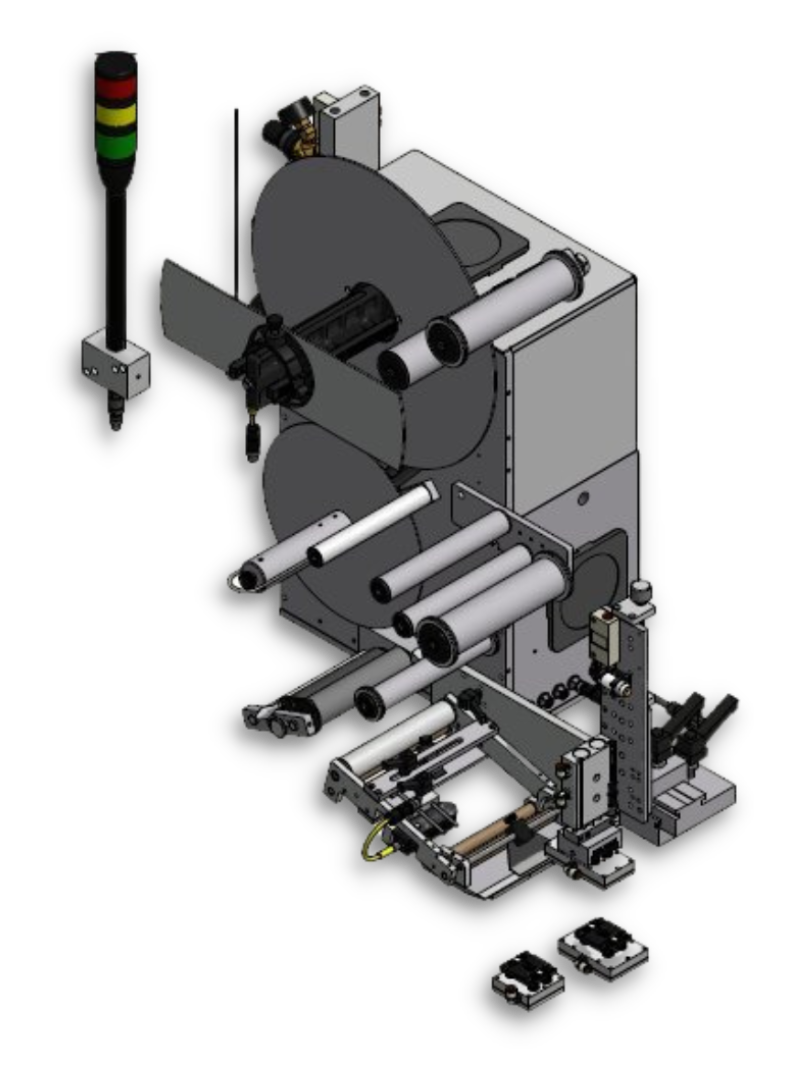

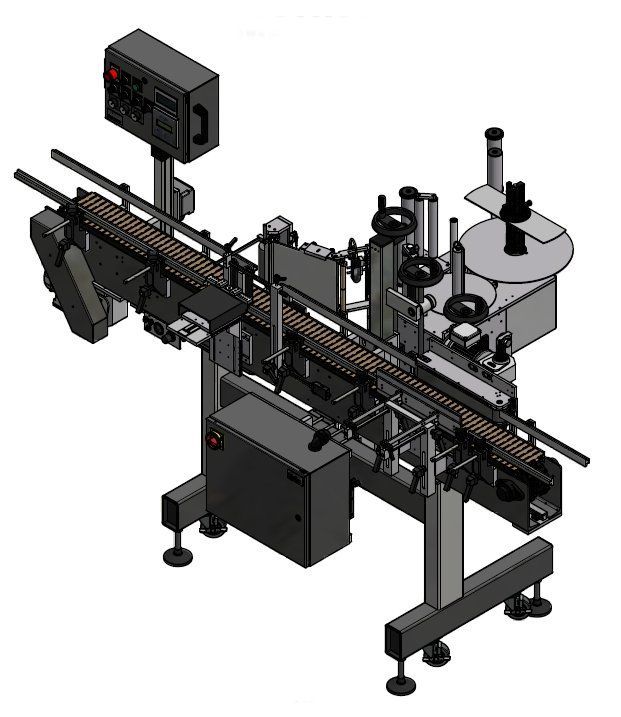

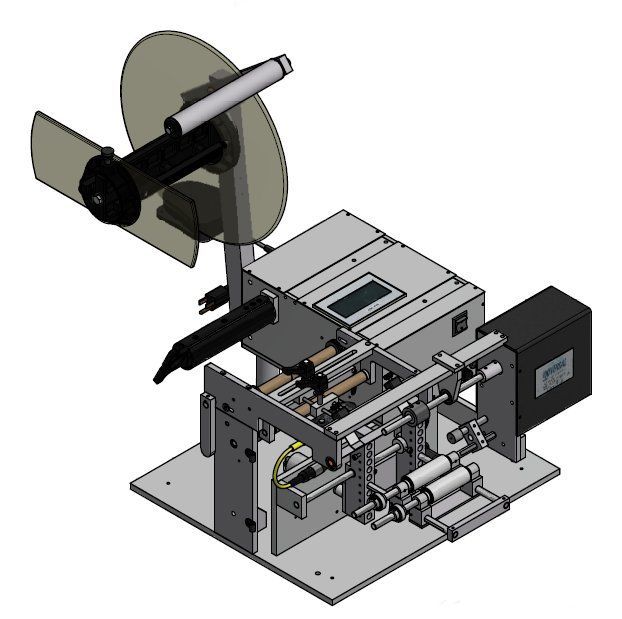

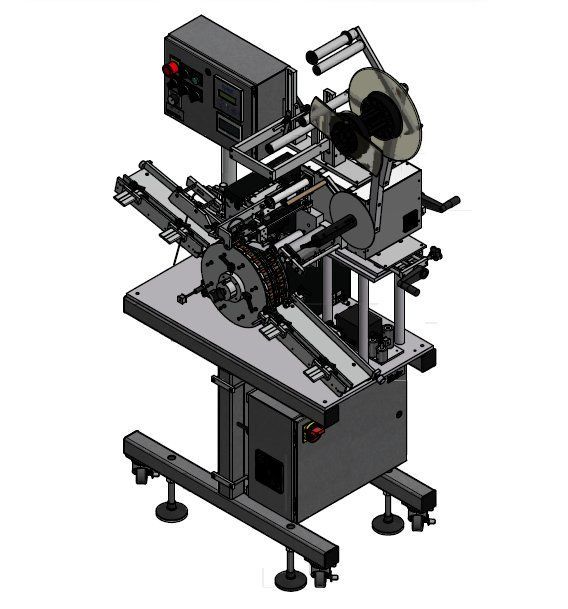

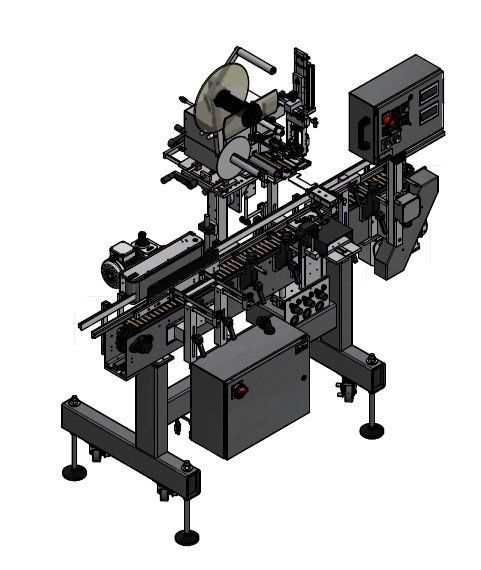

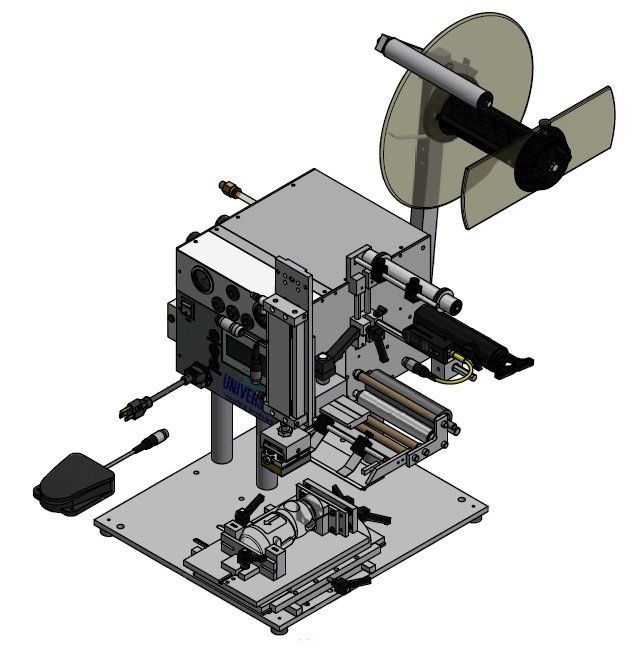

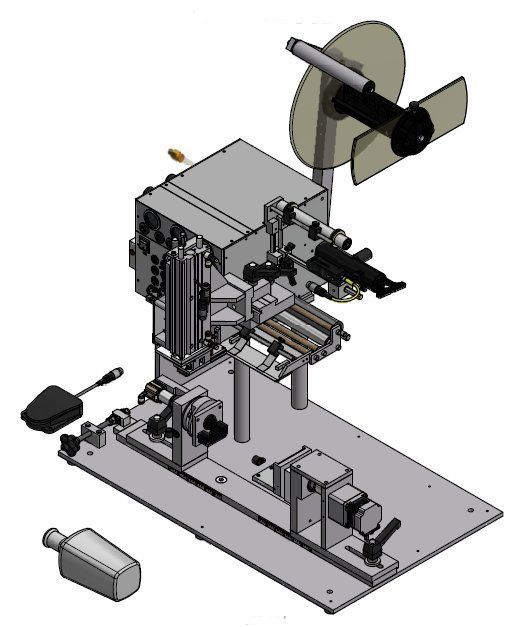

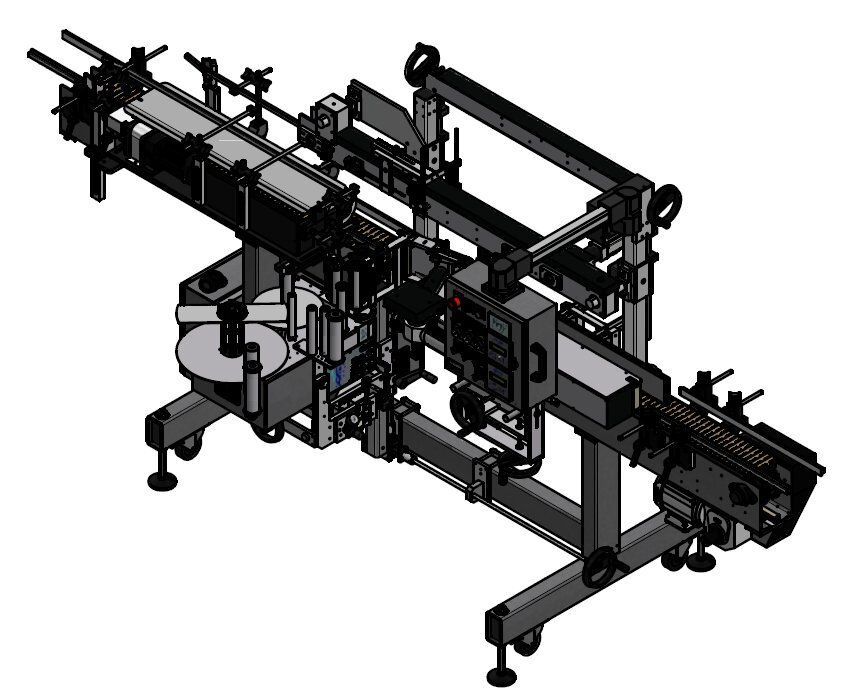

Looking for a reliable and efficient way to label your alcohol bottles? Look no further than our L60 Tamp label applicator with a rotary mechanism! Designed to make labeling your bottles a breeze, this machine features a simple yet effective clamping fixture that securely holds your bottle in place while a tamp head with the label travels to make contact. As the label meets the spinning bottle, it wipes on the label with ease, resulting in a smooth and accurate application every time. This stepper-driven rotary ensures the label center is oriented with the front of the bottle. Also, the fixture can be quickly changed to accommodate different bottle styles. Perfect for small businesses or short-run products, our L60 Tamp Rotary semi automatic label applicator is both speedy and accurate, ensuring that your bottles are labeled quickly and precisely. With its user-friendly design and reliable performance, this machine is the perfect solution for all your labeling needs. A semi-automatic system to apply a label to the neck of the 2 sizes of liquor bottles oriented to the body label. When the operator depresses the footswitch, the fixture rotates, applying the label around the neck in its proper position.