CUSTOM LABELING MACHINERY

CLICK TO CLOSE

Conical or tapered shapes that include crescent-shaped or curved labels are a special challenge for labeling. Universal provides multiple options for the labeling of conical shapes based on speeds, product taper, and multi-label applications. But with all applications, label position accuracy is first and foremost in our designs. For semi-automatic applications (6,000 units or less per day), the modified R310 is a great choice. For automatic applications, the custom R321 or R322 are great high production options.

CLICK TO CLOSE

CLICK TO CLOSE

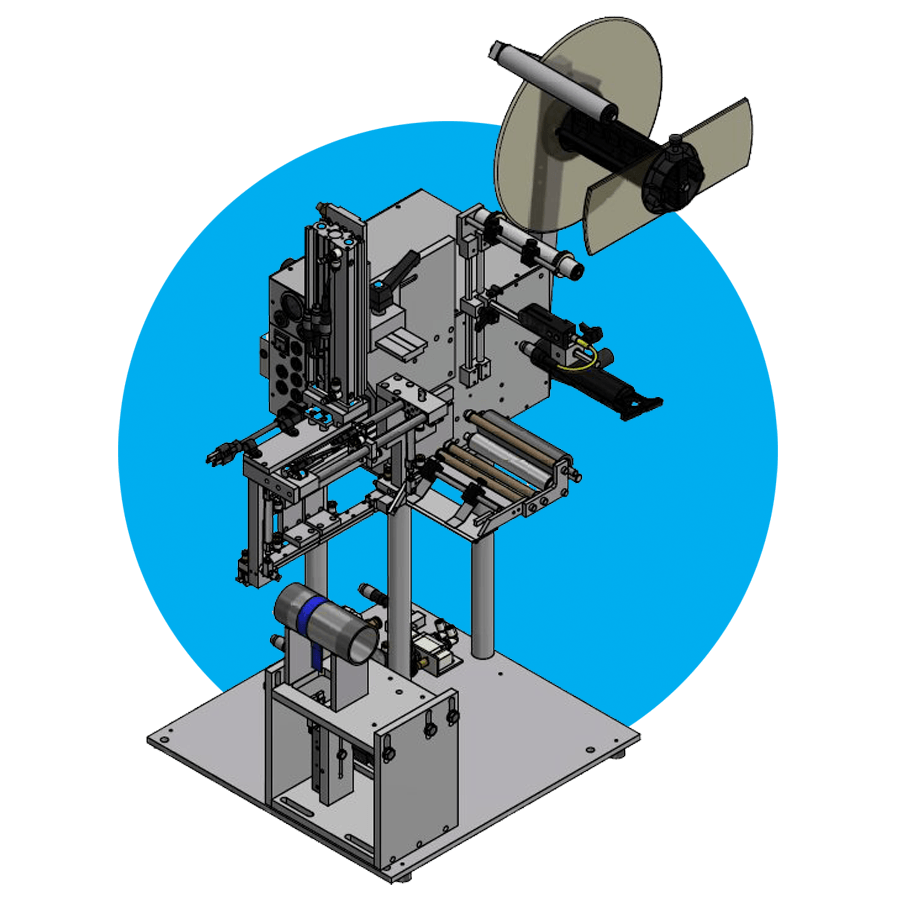

Flagging a label is a way to adhere a label around a product and onto itself. This is most commonly seen with products like wires or tubes where the label information exceeds that of the product size. Universal Labeling provides multiple methods of flagging labels, even to very irregular shaped products. Flag labeling is generally achieved with the L60 label applicator.

CLICK TO CLOSE

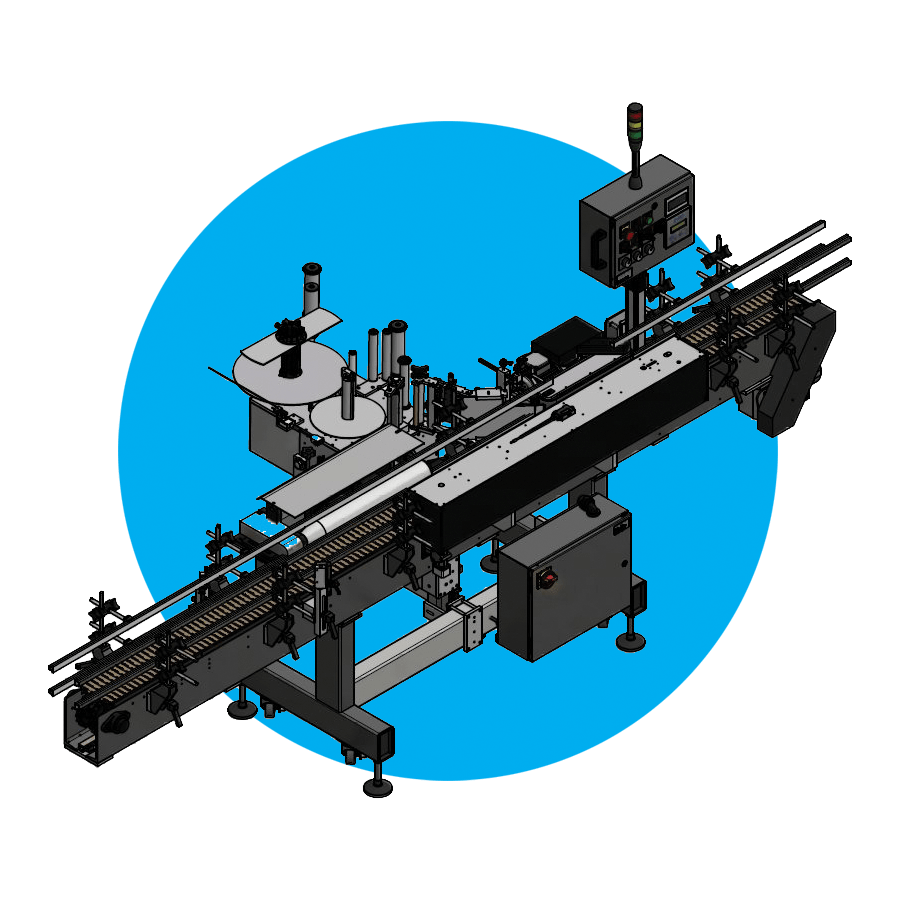

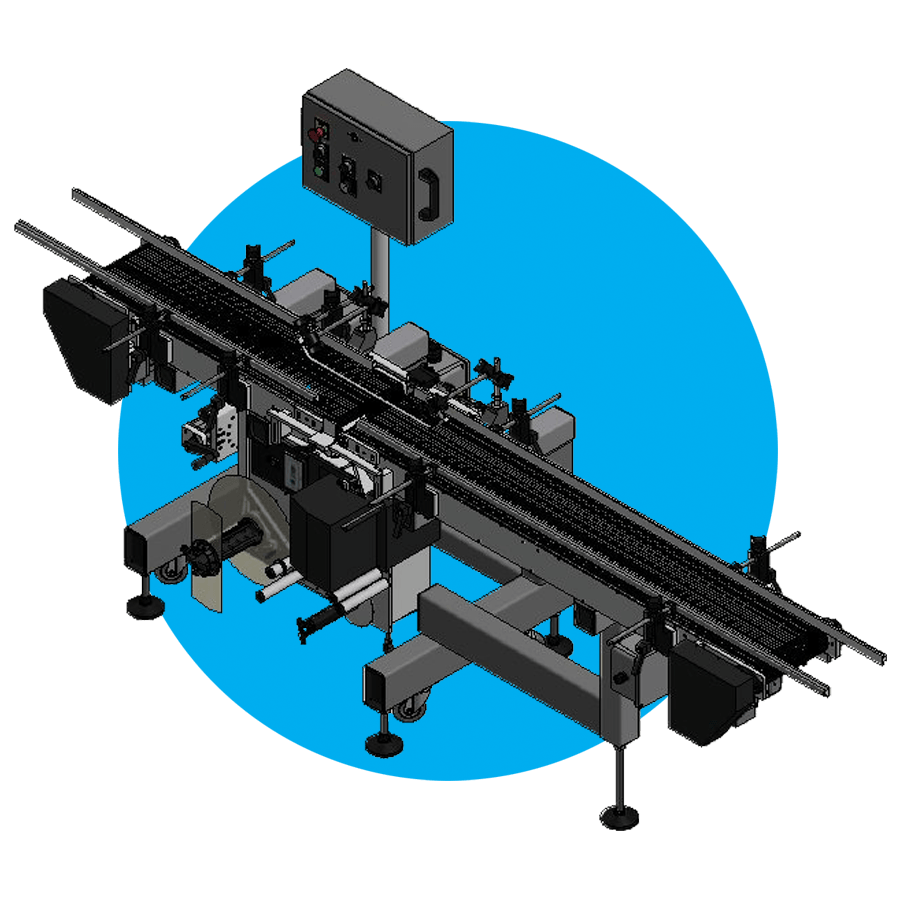

Horizontal roller conveyors are designed by Universal Labeling Systems for small diameter labeling applications. The PLC controlled conveyor systems can be built to index, move continuously, or as a hybrid for both. Horizontal rollers are designed to control small diameter products presenting those products to the SL1500 and SL2000 label applicators.

City skyline

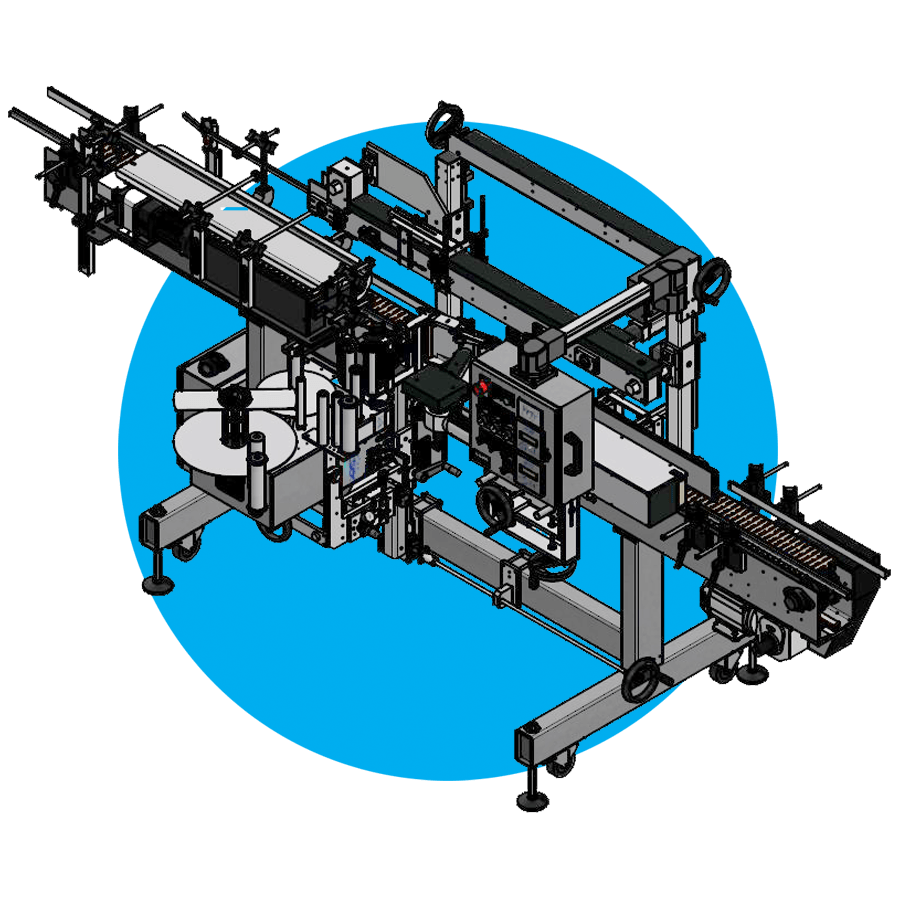

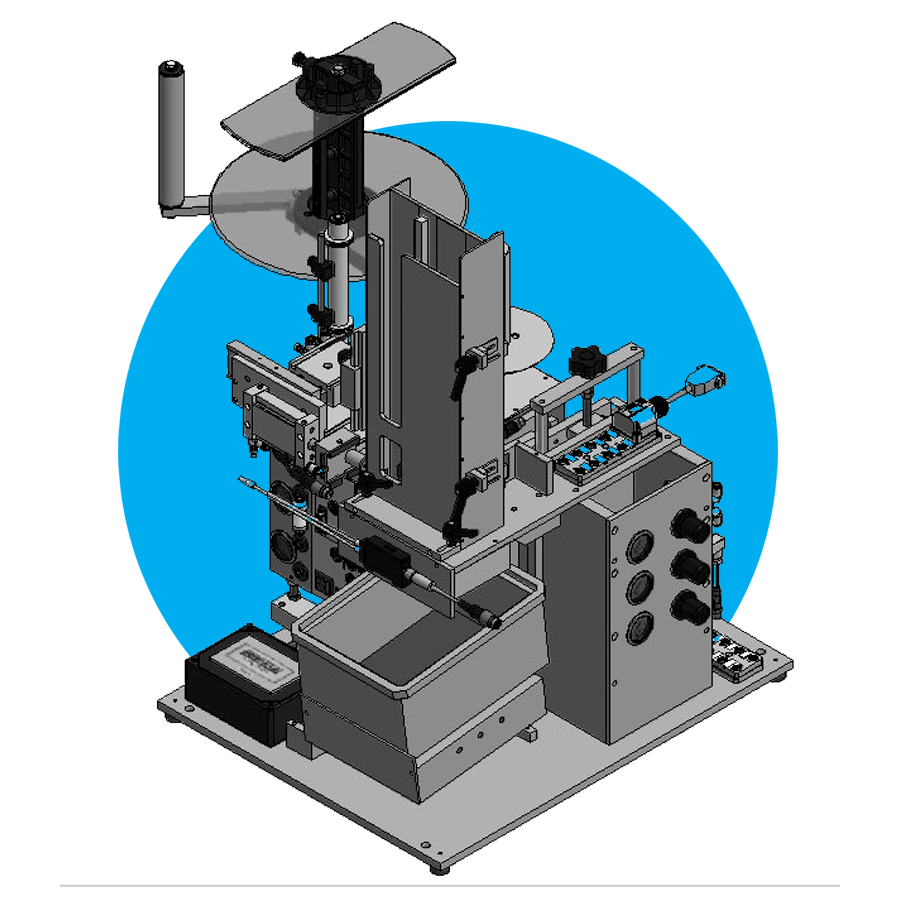

Many decorative labels are designed to be applied around multiple sides of square or rectangular products, or some variation of odd-shaped products. These specialty items require the design of product-specific labeling machinery. Multi-side labeling systems are quite common at Universal Labeling with complete design, manufacturing, testing, and documentation; even in table top models like the L60 semi-automatic.

City skyline

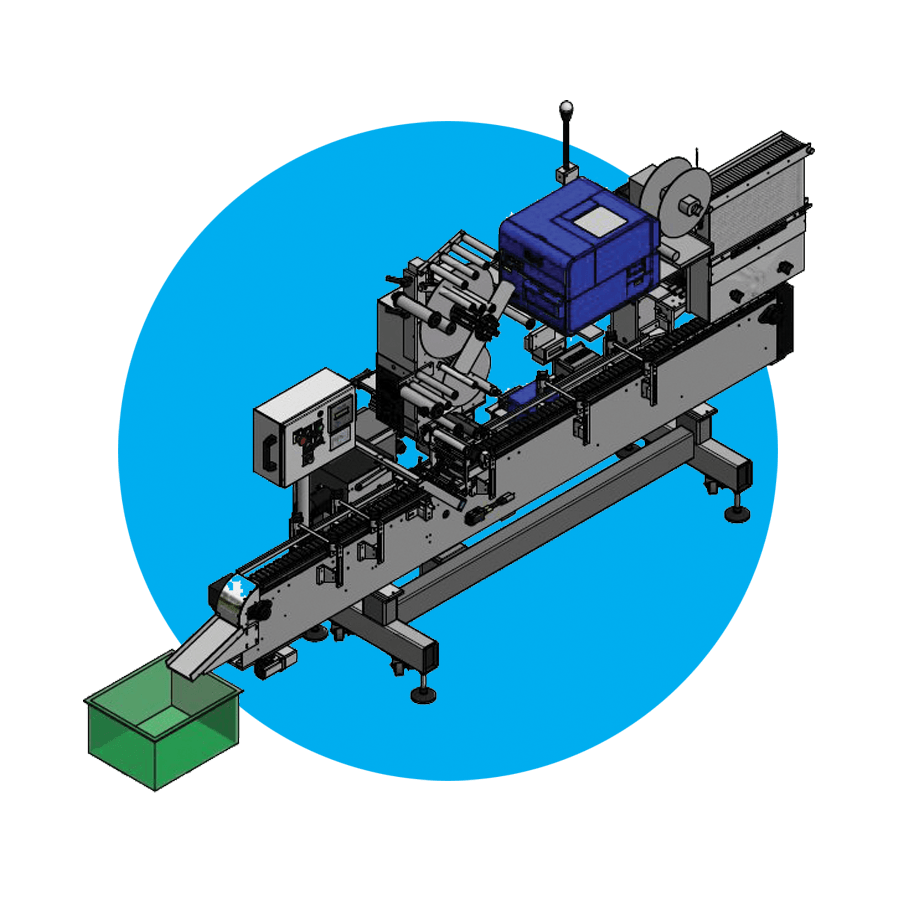

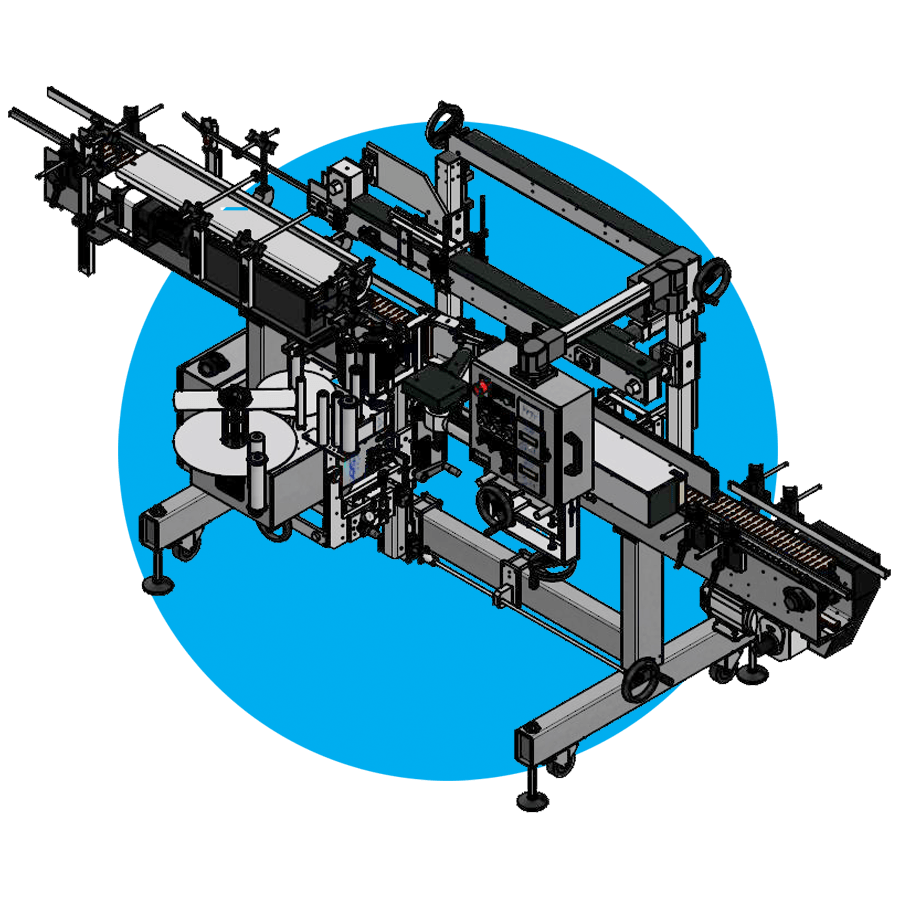

T & B systems are designed to apply “c-wrap” labels, bottom only labels, or top & bottom labels simultaneously. There are three system types that include split belts, interrupted belts, and hugger (side) belt labeling systems. The type of system chosen, is based on the relationship, or size between the product’s contact surface and bottom label. Depending on the label position and product shape, the label can be wiped on or tamped on. The SL1500 and SL2000 can wipe on or merge a label with the motion of the product, or the L60 Tamp or UPA II Printer Applicator can contact the product with the label whether fully in motion or not.

City skyline

Whereas flat surfaces can utilize direct-surface label tamping, contoured or irregular surfaces sometimes require tamping and wiping. This method can reduce or eliminate imperfections like wrinkles and air bubbles to the labeled surface by making corner contact and either shuttling the tamp head or fixture to wipe the label onto the product. The T & W method provides Universal Labeling with the ability to Tamp & Wipe with the L60 or SL1500 label applicators.

City skyline

Vacuum belt wrap systems provide both speed and versatility when labeling a variety of cylindrical or conical shaped products. Labels are fed out onto a vacuum belt wrap unit. The product chases the label, applying it accurately and synchronously. The system can be customized for both straight and crescent-shaped labels, and apply both a single wrap, or front & back labels. Vacuum Bet Labeling adds higher production speeds when integrated into the R321 or R322 round product labeling systems.

City skyline

A vertical trunion is a method of applying labels around cylindrical products at a high rate of speed. The vertical rollers of the trunion control the products from tipping vertically, avoiding label skewing. This method is commonly used in high volume bottling applications, and increases label placement accuracy, especially with products of poor quality. The Vertical Trunion is used exclusively with the R322 high speed round product labeling system.