UNIVERSAL PRINT AND APPLY LABELING SYSTEMS

PRINT AND APPLY LABELING SYSTEMS

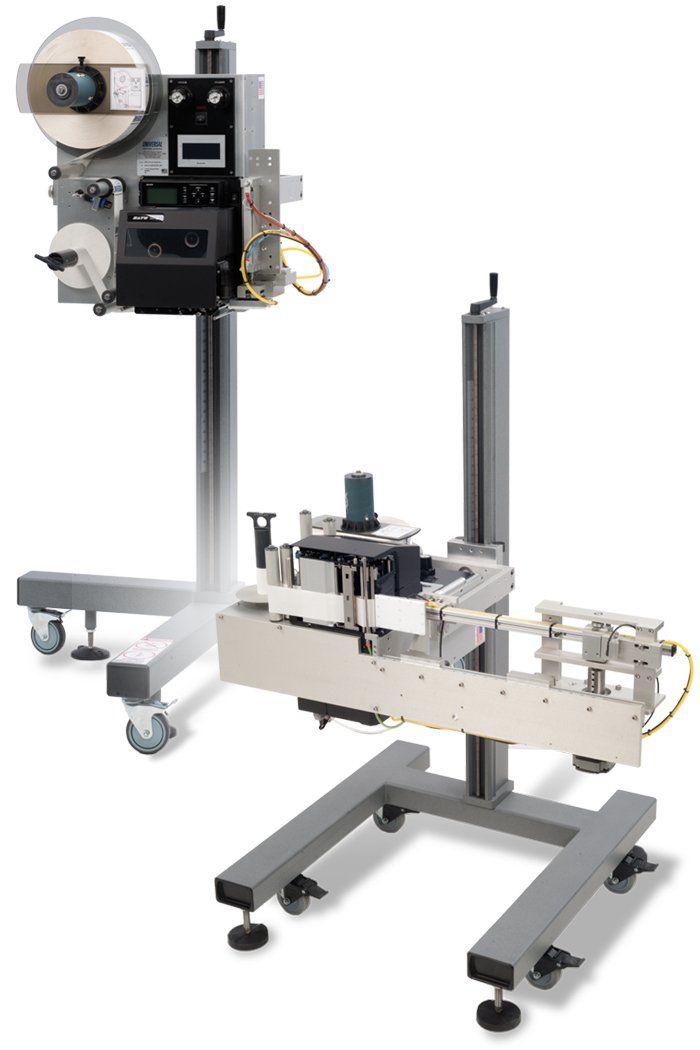

The UPA II

Industrial strength Print & Apply

DOWNLOAD BROCHURE

DOWNLOAD BROCHURE

UPA II FEATURES

UPA II FEATURES

- Industrial strength Print & Apply

- Easy-to-use operator touch screen

- Programmable Logic Controller (PLC)

- “Quick change” Tamp head

- Removable tamp head assembly for easy access to print engine

- Proximity sensor in head “smart head”

- Label out condition

- Label roll capacity: 12” Ø

- Bar code compatible / RFID ready

- Industrial strength Print & Apply

- Easy-to-use operator touch screen

- Programmable Logic Controller (PLC)

- “Quick change” Tamp head

- Removable tamp head assembly for easy access to print engine

- Proximity sensor in head “smart head”

- Label out condition

- Label roll capacity: 12” Ø

- Bar code compatible / RFID ready

UPA II OPTIONS

- Label on head detection

- 3-tier light tree with system fault indicators to include label low, ribbon low, and ribbon out conditions

- External signal output

- Allen Bradley Micro 850 PLC

- Tamp/blow applicator

- Wipe-on applicator

- Radio Frequency Identification (RFID)

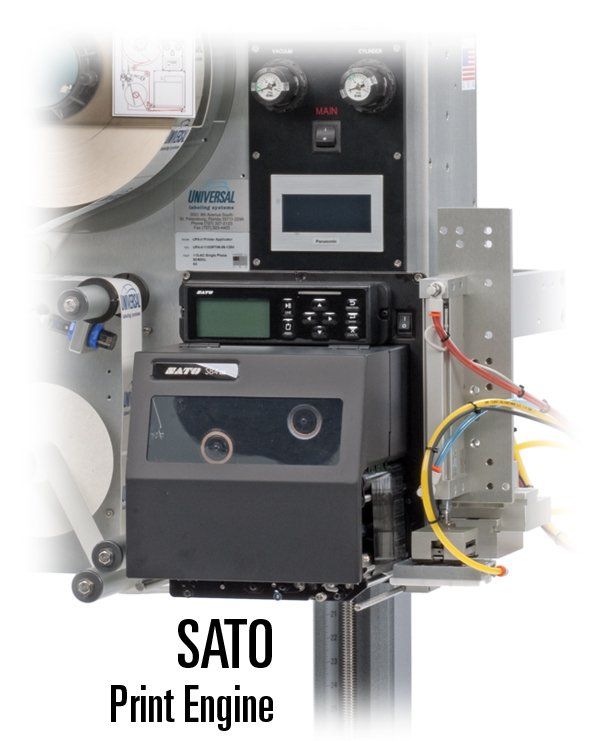

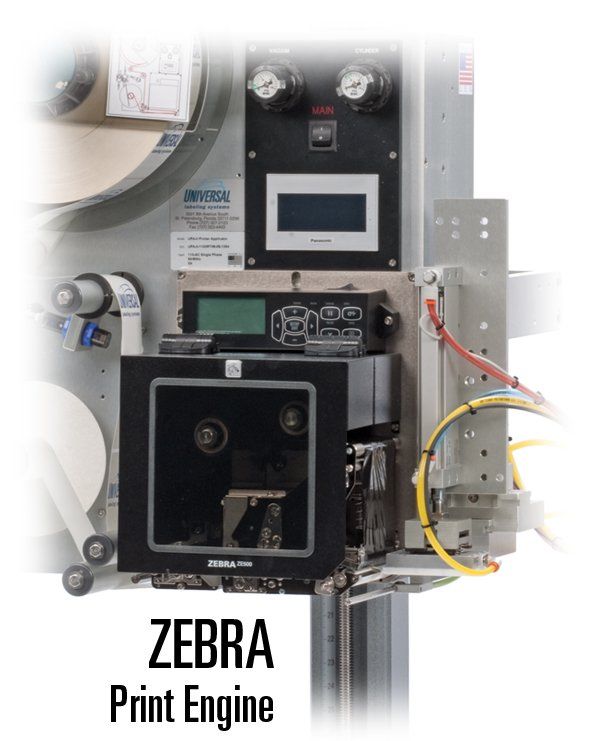

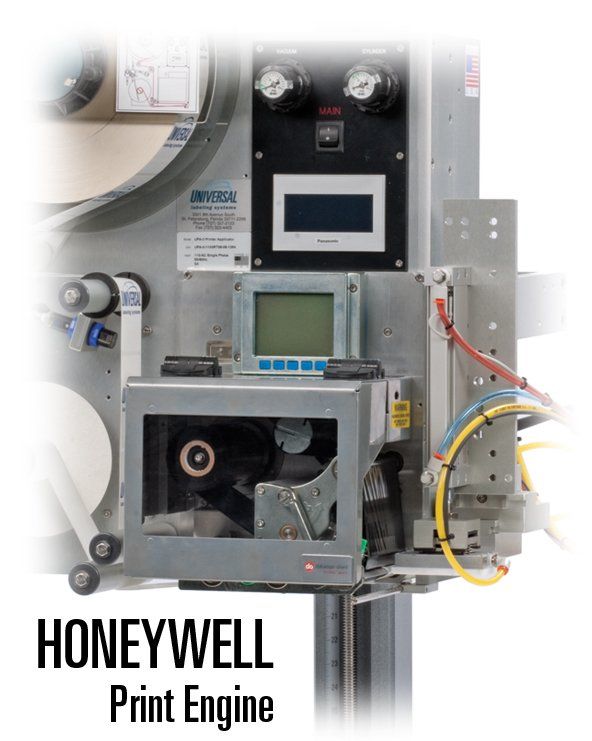

- Choice of Sato or Zebra print engines

UPA II OPTIONS

- Label on head detection

- 3-tier light tree with system fault indicators to include label low, ribbon low, and ribbon out conditions

- External signal output

- Allen Bradley Micro 850 PLC

- Tamp/blow applicator

- Wipe-on applicator

- Radio Frequency Identification (RFID)

- UPA IIe all electric

(stepper driven)

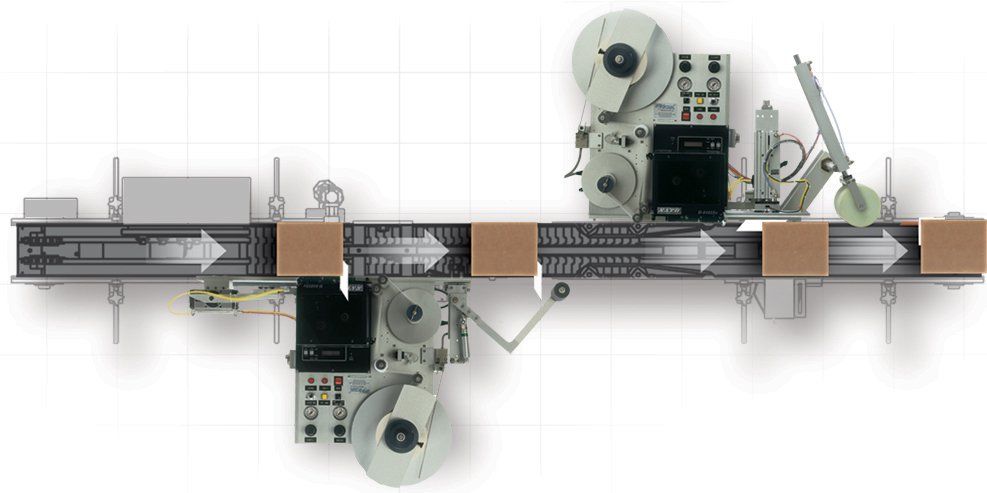

The UPA II CL & CT Corner Leading (CL) & Corner Trailing (CT)

UPA II CL/CT FEATURES

- Programmable Logic Controller (PLC) operational interface

- Swing arm or pneumatic wipe down mechanism

- Heavy duty U or T base stand

- Multiple swing arm options based on your application

UPA II Corner Leading (CL) and Corner Trailing (CT)

- Programmable Logic Controller (PLC) operational interface

- Swing arm or pneumatic wipe down mechanism

- Heavy duty U or T base stand

- Multiple swing arm options based on your application

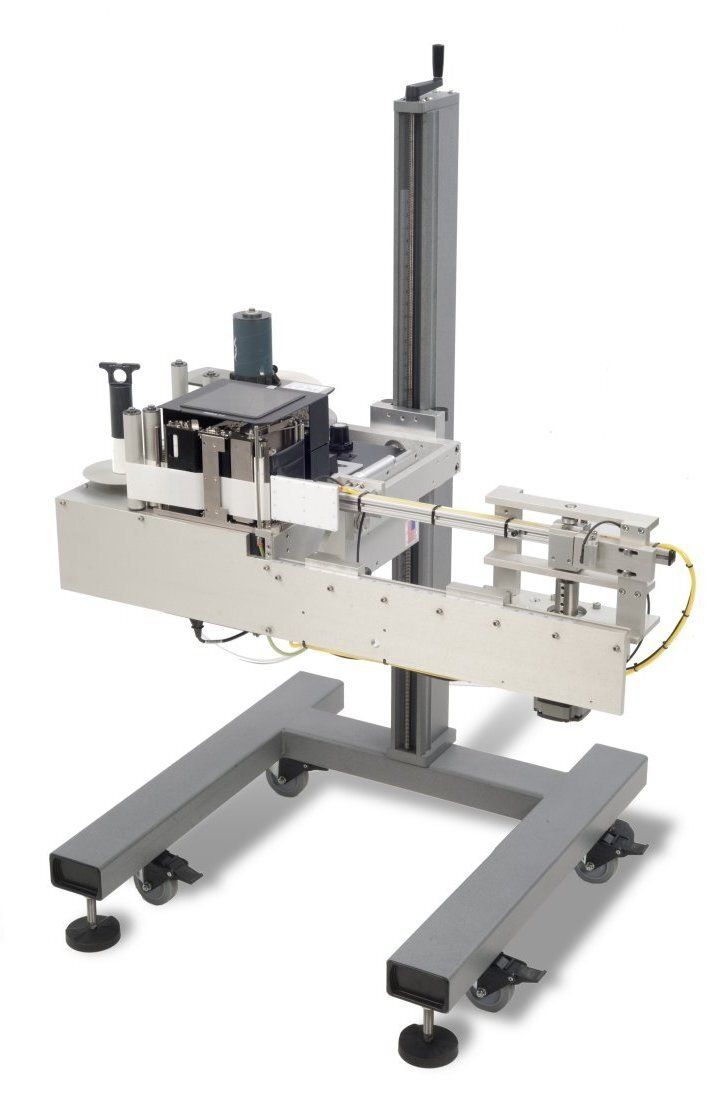

The UPA IIe

All electric Print & Apply

UPA IIe FEATURES

- Energy savi ng all electric Print & Apply

- No compressed air required -no fans

- 25% faster than pneumatic Print & Apply

- Accurate programmable tamp distance

- Industrial strength Print & Apply

- Easy-to-use operator touch screen

- Programmable Logic Controller (PLC)

- “Quick change” Tamp head

- Removable tamp head assembly for easy access to print engine

- Proximity sensor in head “smart head”

- Label out condition

- Label roll capacity: 12” Ø

- Bar code compatible / RFID ready

UPA IIe OPTIONS

- Label on head detection

- 3-tier light tree with system fault indicators to include label low, ribbon low, and ribbon out conditions

- External signal output

- Allen Bradley Micro 850 PLC

- Tamp/blow applicator

- Wipe-on applicator

- Radio Frequency Identification (RFID)

- Choice of Sato or Zebra print engines

UNIVERSAL PRINT AND APPLY LABELING SYSTEMS

Print & apply labeling lets users create and apply labels directly onto a product and its packaging. Thermal transfer labels can carry data such as alphanumeric text, barcodes, serialization, 2D codes, QR codes, and graphics as a more accurate and cost-effective way to design and apply labels. The most common use of Print & Apply is on boxes and cartons. At Universal Labeling we take this method a step further by coupling the technology with our made-to-order product handling. This combination offers our customers print & apply technology to a multitude of applications like industrial components, durable goods, health & beauty, medical, and pharmaceutical.

The UPA IIe, all electric printer applicator that features an energy saving all electric system. This means no compressed air required and no air contamination. The unit is 25% faster than traditional pneumatic print & apply, has an accurate programmable tamp distance, and is the most rugged print & apply in the industry. And like all UPA’s, we include quick release tamp heads, a conventional air assist tube without fans, and a quick release slide mount for easy access to the print engine.